When it comes to reliable and efficient industrial biomass boilers, Fangkuai Boiler is the leading brand you can trust. In this article, we’ll explore how an industrial biomass boiler works, its benefits, and the various factors to consider when selecting a biomass boiler for your plant and provide a useful cost comparison chart to help you make an informed decision.

What is an industrial biomass boiler?

An industrial biomass boiler is a type of boiler that uses biomass, such as wood chips, agricultural waste, or other organic materials, as fuel to produce steam or hot water for various industrial processes and applications.

How does an industrial biomass boiler work?

An industrial biomass boiler works by burning the biomass fuel inside the combustion chamber, which heats up the water-containing pipes. The heat will transfer from the combustion chamber to the water pipes, turning the water into steam. The steam then moves through pipes and is distributed throughout the building or used to power industrial processes, turbines, or generators. The combustion process also generates flue gases, which are treated and released through the boiler’s exhaust system.

What is the benefit of industrial biomass boilers?

- Environmentally friendly: Industrial biomass boilers use renewable energy sources such as wood chips, pellets, or logs, to produce heat. Burning biomass produces fewer emissions than non-renewable sources such as oil and gas.

- Cost-effective: Biomass fuels are generally less expensive than fossil fuels such as oil and gas. The operating costs of industrial biomass boilers are lower, which helps save businesses money in the long run.

- Versatile: Industrial biomass boilers are versatile and can be used for multiple purposes, such as generating electricity, heating buildings, or powering industrial processes.

- Energy independence: A biomass boiler can be used to generate energy on-site, making businesses less reliant on external energy sources.

- Supports local economy: Biomass can be sourced locally, which supports local economies and reduces transportation costs.

- Reduced carbon footprint: Biomass is a renewable energy source, burning biomass produces lower emissions than non-renewable sources such as oil and gas.

In summary, industrial biomass boilers are a great option for businesses and industries seeking to reduce their carbon footprint, save money on energy costs, and become more energy independent.

What fuel does an industrial boiler use?

An industrial boiler can use various types of fuel based on its design and availability. The most common fuels used in industrial boilers are:

- Natural gas: It is a clean and efficient fuel with a low carbon footprint, making it a popular choice for industrial boilers.

- Oil: Industrial boilers can use different types of oil, such as diesel oil, heavy oil, or residual oil. However, burning oil can produce harmful emissions and requires frequent maintenance.

- Coal: Coal is a widely available and inexpensive fuel that has been used in industrial boilers for a long time. However, burning coal produces a lot of pollution and contributes to greenhouse gas emissions.

- Biomass: Biomass fuels, such as wood chips, sawdust, or agricultural waste, are increasingly being used in industrial boilers as a sustainable and renewable fuel source.

- Electricity: In some cases, industrial boilers can use electricity as a source of power.

Overall, the choice of fuel for an industrial boiler depends on the availability, cost, and environmental impact of the fuel, as well as the efficiency and operating cost of the boiler itself.

How do I choose a biomass boiler for my plant?

To choose the right biomass boiler for your plant, you should consider the following factors:

- Fuel type: Different biomass fuels have different combustion properties, and the choice of fuel affects the efficiency and performance of the boiler. Consider the availability, cost, and quality of the biomass fuel in your area.

- Boiler size: The size of the boiler depends on the heating needs of your plant, and the amount of biomass fuel you have available. A larger boiler can be more efficient, but also requires more space and has higher installation costs.

- Efficiency: Look for boilers with high-efficiency ratings to minimize fuel consumption and reduce operating costs. Also, consider the emissions of the boiler and make sure it meets environmental regulations.

- Maintenance requirements: Biomass boilers require regular maintenance to ensure efficient and safe operation. Consider the amount of maintenance that the boiler requires and the availability of qualified technicians in your area.

- Cost: The cost of the biomass boiler includes installation, maintenance, and fuel costs.

You should consider the total cost of ownership over the lifespan of the boiler to make an informed decision.

How much does an industrial biomass boiler cost?

The cost of an industrial biomass boiler can vary based on factors such as the size of the system, the type of fuel used, and the efficiency of the boiler.Initial investments can range from $5,000-$100,000. Additionally, you need to consider ongoing operating costs such as fuel, labor, and maintenance. However, the long-term savings in energy costs and the environmental benefits often make an industrial biomass boiler a worthwhile investment.

| Boiler Size | Body Cost | Installation Cost | Fuel Type | Fuel Cost |

|---|---|---|---|---|

| 1-10t/h | $50,000 | $10,000 | Wood Chips | $5,000 |

| 1-10t/h | $50,000 | $10,000 | Pellets | $6,000 |

| 10-20t/h | $100,000 | $20,000 | Wood Chips | $10,000 |

| 10-20t/h | $100,000 | $20,000 | Pellets | $12,000 |

| 20-50t/h | $200,000 | $40,000 | Wood Chips | $20,000 |

| 20-50t/h | $200,000 | $40,000 | Pellets | $24,000 |

| >50t/h | $500,000 | $100,000 | Wood Chips | $50,000 |

| >50t/h | $500,000 | $100,000 | Pellets | $60,000 |

Conclusion.

In conclusion, selecting the right industrial biomass boiler for your plant is a critical decision that requires careful consideration of various factors, including boiler size, fuel type, and costs. Don’t hesitate to consult with the experts at Fangkuai Boiler to help you find the perfect solution for your facility and enjoy the benefits of a greener, more sustainable energy source. If you want to learn about the detailed parameters and prices of industrial biomass boilers, please contact us: at +0086 186-2391-5479.

FAQs.

What is the capacity of an industrial biomass boiler?

The capacity of industrial biomass boilers can range from 8 to 120 Tons/hr, which is suitable for producing steam and hot water for various industrial processes and applications.

How efficient is biomass industrial energy?

Biomass industrial energy is highly efficient, with some systems achieving up to 90% efficiency. This is because biomass is a renewable resource that can be sourced sustainably.

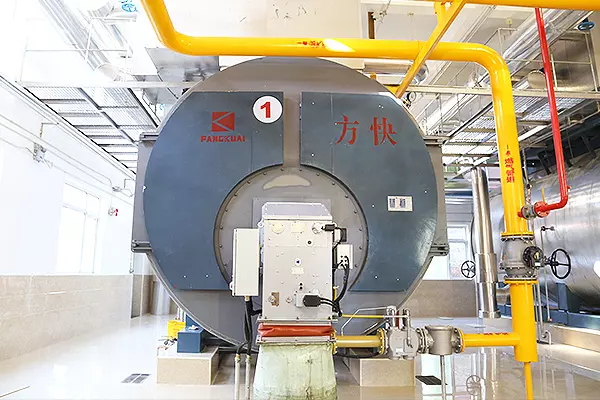

Which company makes biomass-fired boilers?

Many companies manufacture biomass-fired boilers, including industry leaders like Fangkuai Boiler, Babcock & Wilcox, Hurst Boiler & Welding Company, Inc., and Valmet Corporation.

How much does it cost to run a biomass boiler?

The cost of running a biomass boiler depends on various factors. Manual-fed log boilers can cost between $4,000 to $10,000, while automatically-fed pellet boilers may range from $10,000 to $20,000.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies