Introduction

Gas steam boilers provide an effective way to heat homes, businesses, and other buildings. These systems utilize natural gas or propane to heat water in a boiler system, generating steam that is then distributed via pipes and radiators for space heating.

Compared to electric or oil-fired boilers, gas steam boilers offer more energy-efficient operation, lower monthly heating bills, and quicker installation. Gas-fired steam boilers come in a wide array of sizes and BTU outputs to match any building’s specific heating requirements.

In this comprehensive guide, we will cover everything you need to know if you are considering installing a new or replacing an existing gas steam boiler system. You will learn how gas steam boilers work, their advantages, approximate costs, top brands to consider, proper maintenance, and more.

Whether you need a residential boiler or a high-capacity commercial unit, this article will provide valuable information to guide your gas steam boiler purchase or upgrade decision.

How do gas steam boilers work?

Gas steam boilers provide heat through a closed-loop system that utilizes natural gas combustion, heat transfer, and steam generation. Here is a step-by-step overview of how they work:

Gas combustion

Gas or propane is delivered through a gas line to the boiler. The gas is then mixed with air in the burner, where a pilot light ignites it. This combustion process heats a heat exchanger.

Heat transfer

The heat from combustion is transferred to the water reservoirs in the heat exchanger. This heated water begins to boil and convert into steam.

Steam generation

As more heat is continually transferred to the water, steam is produced and distributed through pipes to radiators and heating units throughout the building. This provides heat to the various rooms and spaces.

There are a few main types of gas steam boilers:

- Fire Tube – This style has hot gases from combustion passing through tubes surrounded by water.

- Water Tube – Combustion gases surround water tubes in this design. It is more efficient.

- Condensing – These units have a secondary heat exchanger to capture additional heat.

Benefits of gas steam boilers

There are many advantages to using a gas steam boiler system:

More energy efficient

Gas steam boilers can convert over 80% of their fuel to usable heat. This makes them more efficient than electric or oil boilers.

Lower operating costs

With gas prices being lower than electricity and oil, gas steam boilers have much lower fuel costs. This saves significantly on monthly heating bills.

Available in range of BTU outputs

Gas steam boilers come in a wide range of BTU outputs from 40,000 to 1.5 million. This makes it easy to find a unit matched to your building’s specific heating needs. A 150,000 BTU gas steam boiler would be ideal for a large commercial space.

Compact size

Even large, high BTU output gas steam boilers have a compact footprint. This saves on space requirements.

Easy installation and maintenance

Gas steam boilers can be installed more quickly than electric or oil units. They also have less maintenance needs overall.

Lower emissions

Gas steam boilers produce fewer emissions than oil or coal units. This makes them a more environmentally friendly option.

When it comes to efficiency and performance, it’s hard to beat gas steam boilers. Their gas burner design makes them one of the most energy-efficient boiler options.

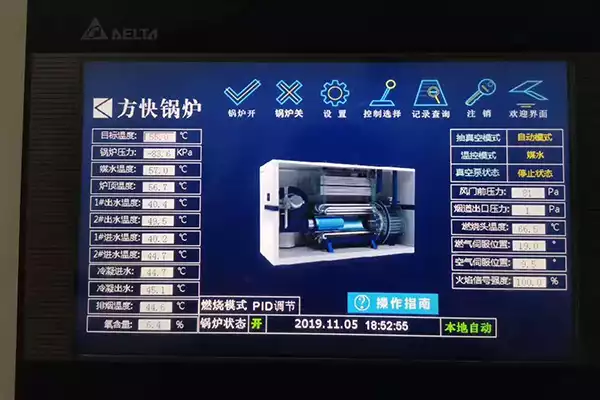

What are the components of a gas-fired steam boiler?

A gas steam boiler consists of several key components that allow it to operate efficiently. These components include:

- Burner: The burner is responsible for igniting the fuel (natural gas or propane) and generating heat. It also controls the amount of fuel and air supplied to the boiler.

- Heat exchanger: The heat exchanger is a device that transfers the heat generated by the burner to the water in the boiler. It is usually made of metal and has a large surface area to maximize heat transfer.

- Water tank or boiler: The water tank or boiler contains water heated by a heat exchanger. It may also have sensors and controls to regulate water temperature and pressure.

- Control system: The control system includes thermostats or other temperature sensors, and various valves and controls that regulate the flow of water and steam throughout the system.

- Pressure relief valve: The pressure relief valve is a safety device that can release excess pressure in the boiler to prevent accidents.

- Circulation pump: The circulation pump circulates water or steam through the pipes and radiators in the building. It helps distribute heat evenly and efficiently.

- Expansion tank: An expansion tank is a small water tank attached to the boiler that allows water and steam to expand when heated.

- Chimney or Vent: A chimney or vent allows exhaust gases to exit the boiler safely.

- Flue gas analyzer: This is a tool used to measure the composition of exhaust gas to ensure efficient combustion and safe operation of the boiler.

- Combustion Air Inlet: This part introduces fresh air for the combustion process.

Top gas steam boiler brands

When selecting a gas steam boiler, choosing a leading brand from a reputable manufacturer is highly recommended. Here are several of the top companies producing gas steam boilers:

Weil-McLain

- Known for performance, reliability, and energy efficiency

- Offer a wide variety of sizes ranging from 3,400 – 10.5 million BTUs

- Provide both condensing and non-condensing boiler models to suit different needs

- Prices for their gas steam boilers range from $2,500 on the low end up to $30,000 for larger commercial units

- Units feature rugged cast iron or steel construction and fire tube or water tube heat exchanger designs

- Weil-McLain boilers have up to 94% AFUE ratings for gas steam boilers

- They offer comprehensive warranties of up to 12 years for the heat exchanger and 5 years for parts

Burnham

- Over 140 years of experience manufacturing boilers

- Utilize high-quality components and robust construction in their gas steam boilers

- Offer both horizontal and vertical configurations to fit different installation spaces

- Provide gas steam boilers with outputs from 400,000 BTU to 14 million BTU

- Known for their cast iron sectional boilers that offer flexibility for installation

- Burnham’s Independence model has a large steam chest and 2.5” supply tappings for good steam capacity

- Units include energy-saving controls like outdoor reset and night setback

Lochinvar

- Well-known as a leader in high-efficiency boilers

- Their gas steam boilers range from 500,000 to 15 million BTU capacities

- Offer flexible control packages with monitoring capabilities for large commercial applications

- Designed and built specifically for commercial and industrial settings

- Feature down-fired combustion and multiple pass heat exchangers for maximum efficiency

- Low NOx designs available to meet emissions regulations

- Warranties include 10 years on the heat exchanger and 5 years on the parts

Rite engineering

- Provider of gas steam boilers for over 70 years

- Focus on easy maintenance and reliable performance

- Offer fire tube and water tube models from 20 to 2,500 HP

- Units include rugged steel construction and efficient burner systems

- Known for their comprehensive digital controls on gas steam boilers

- Prices range from $5,000 to $50,000 for large commercial boilers

When selecting a brand, prioritize those with good warranties, high-quality components, certifications, and positive customer reviews. The top gas steam boiler brands have proven track records of performance and longevity.

What is the price for a gas steam boiler?

The cost of a gas steam boiler depends on the size, BTU output, brand, and features. Here are some factors that influence the price:

BTU Output

As the BTU output goes up, so does the purchase price. Small residential units may start around $2,000. Large commercial gas steam boilers over 1 million BTUs could cost $50,000 or more.

Brand

Well-known brands like Weil McLain, Burnham, and Lochinvar will be pricier than generic boilers. You pay for quality components and longer warranties.

Efficiency

More efficient ENERGY STAR-rated gas steam boilers will cost more upfront but save on fuel costs long-term.

Features

Units with smart WiFi controls, multi-zoning, and advanced monitoring capabilities will add to the price.

Overall installation costs will also depend on whether you need new gas lines, venting, permits, and labor. However, gas steam boilers provide much lower monthly utility bills, so the upfront costs pay off in the long run.

| Boiler Size (T/h) | Fuel Type | Efficiency (%) | Estimated Cost (USD) |

|---|---|---|---|

| 1-10 | Natural Gas | 85-94 | 3,500 – 8,500 |

| 95-98 | 5,000 – 10,000 | ||

| Propane | 85-94 | 3,800 – 8,300 | |

| 95-98 | 5,300 – 10,800 | ||

| 10-20 | Natural Gas | 85-94 | 8,500 – 15,500 |

| 95-98 | 9,000 – 17,500 | ||

| Propane | 85-94 | 8,800 – 15,800 | |

| 95-98 | 9,300 – 18,500 | ||

| 20+ | Natural Gas | 85-94 | 12,500+ |

| 95-98 | 15,000+ | ||

| Propane | 85-94 | 15,500+ | |

| 95-98 | 18,000+ |

New vs. replacement gas steam boilers

There are several factors to weigh when considering a new gas steam boiler vs replacing an existing one:

Age and condition

Once a gas boiler reaches 15-20 years old, its efficiency and performance start to decline. Replacing an aging, inefficient unit with a new gas steam boiler can significantly improve your building’s heating capabilities.

Needed repairs

If an old boiler needs major component replacements like the heat exchanger or burner, it often makes more sense to invest in a new one.

Improved efficiency

A new ENERGY STAR-rated gas steam boiler will be much more efficient than an older model. Even a 5-10% improvement in efficiency results in significant annual cost savings.

Advanced features

New gas steam boilers come with smart controls, easier maintenance, multi-zoning capabilities, and other features that improve performance.

Longer lifespan

A new gas steam boiler will have an estimated lifespan of 20-30 years. Investing now avoids another replacement down the road.

Reduced emissions

Upgrading to a new gas steam boiler will reduce your building’s emissions and environmental impact.

Before deciding to replace your gas steam boiler, do a cost analysis on the payback time. Get quotes on new gas boiler installation and calculate the potential energy savings. If you will recoup the costs within 5-7 years, replacement is likely the better investment.

Maintaining gas steam boilers

Proper maintenance keeps a gas steam boiler running safely and efficiently. Here are some tips:

- Have professional annual tune-ups done to inspect components and perform deep cleaning.

- Check that safety valves, water level controls, and pressure gauges are working properly each month.

- Follow manufacturer guidelines for draining and refilling the boiler annually.

- Keep the area around the boiler free of dust and debris.

- Replace old pipes and fittings that show corrosion.

- Monitor for any leaks, odd noises, or temperature fluctuations regularly.

- Have combustion efficiency tested every few years.

Performing basic monthly maintenance checks and having annual professional tune-ups done will keep your gas steam boiler operating at peak efficiency for decades.

Conclusion.

Gas steam boilers provide an efficient, low-emission method of heating. They utilize natural gas combustion to transfer heat to water and generate steam. With benefits like energy efficiency, lower operating costs, compact sizing, and easy maintenance, gas steam boilers are a great option for both residential and commercial buildings. We covered the inner workings, costs, top brands, and maintenance best practices to consider when using a gas-fired steam boiler. Just be sure to have the proper BTU output size and features for your specific building heating needs.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies