Introduction

It’s important to understand what condensing boilers and non-condensing boilers offer. So that you can make an informed decision about which one is best suited for your needs. In this guide, we’ll explain the difference between condensing and non-condensing boilers. And talk about which type might be best for your home!

What is the difference between a condensing boiler and a non-condensing?

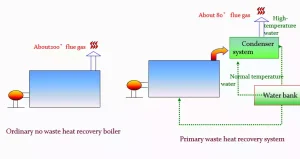

In a nutshell, condensing boilers use the heat from exhaust gases to provide hot water. Non-condensing boilers do not.

A condensing boiler is the use of an efficient condensing waste heat recovery device to collect high-temperature flue gas in the sensible heat and water vapor condensation release of latent heat. In contrast, non-condensing boilers do not recover heat from their fuels at all. Their exhaust gases are vented directly into the atmosphere or piped into flues shared with other appliances like ranges or ovens.

Energy Efficiency

The thermal efficiency of traditional boilers using high calorific value fuels is generally 70%-80%. While the thermal efficiency of condensing boilers under the same conditions can reach up to 98% in actual production, and can even reach a higher level.

On average, a condensing boiler will use about 25% less fuel than its non-condensing counterpart over its lifetime. A non-condensing boiler will lose around 30% of its energy through venting, whereas a condensing boiler only loses about 5%.

Therefore, condensing boilers are more energy efficient than non-condensing boilers. A condensing boiler uses less fuel and produces less CO2, which means you can save money on your heating bills and reduce your carbon footprint at the same time.

Typical Lifespan

The average life expectancy of a high-quality, modern condensing boiler is 30 years, while most non-condensers are expected to last no more than 15 years. This can save you money in the long run and make your home more comfortable year after year.

Condensing Boilers Pros

- They are more efficient. Condensing boilers use fully enclosed combustion, the combustion flame is surrounded by all the heat exchangers, thus effectively reducing the heat of the furnace itself.

- They are more reliable. Condensing boiler combustion chambers are generally made of stainless steel and cast-silicon aluminum, which are more corrosion-resistant. So the lifespan can be doubled.

- They are easier to install. Especially if you have a smaller space to work with, as they can be fitted into existing pipework or installed in an isolated room with just a few basic tools needed for installation (and no need for scaffolding).

- They’re also durable. Because they don’t use hot water from your storage tank until it’s needed, there’s less chance of damage from overuse or clogging caused by sediment buildup inside the pipes leading up from your water source (such as well pumps).

Condensing Boilers Cons

- Higher initial cost: The higher initial cost of a condensing boiler can be offset by savings in energy bills over the lifetime of your boiler.

- More maintenance: You will need to check and clean your condensing boiler more regularly than you would with an ordinary non-condensing boiler. This is because it has a closed circuit system, so there are fewer places for debris and other materials to collect in the unit itself.

- Larger size: Condensing boilers tend to be larger as they have more parts than non-condensing ones; however, this does mean that you’ll get better performance out of them when it comes down to heating up water faster!

- May require more space: If you don’t have enough room then consider installing two smaller units instead (one for hot water) rather than one large one.

Non-condensing Boilers Pros

- No need for a condensing unit: Non-condensing boilers do not require a condensing unit, which means they can be installed in your loft or garage. This makes them cheaper to install and maintain than their condensing counterparts.

- Less expensive to maintain: The cost of servicing non-condensing boilers is lower than that of maintaining a boiler with an integrated heat exchanger (IHX). A typical annual service for an IHX system costs around $300. Whereas servicing a non-condensing gas boiler will only set you back about $100-$200 per year. It’s a significant difference!

- Good for homes with existing radiators or hot water tanks: If you have radiators already in place when installing a new heating system, then opting for one without IHXs will save you money on installation costs while still providing efficient heating throughout your home.

Non-condensing Boilers Cons

- Lower efficiency. Non-condensing boilers use more energy to heat water, as they’re not able to capture the heat from the exhaust gases. This means that you’ll have to spend more on fuel, which can add up over time.

- Higher repair costs. Because non-condensing boilers don’t have an internal condenser (a device that collects and expels water vapor). They’re more likely than their condensing counterparts to break down and require repairs or replacement parts. Which can be costly!

- Limited space for larger homes. If you live in a large house with multiple bathrooms or showers that need heating up at once. Then consider getting yourself a larger model so that everyone gets enough hot water when they need it!

Initial Cost

The average price of a high-quality non-condensing boiler ranges from $1,500 to $2,500 depending on its size and features. Meanwhile, an efficient condensing model can cost anywhere from $4,000 – $6,000. Or more depending on its efficient cy rating (ER) and other factors like ease of installation etc…

Obviously, the initial cost of condensing boilers is higher than that of non-condensing boilers. The reason is that it’s not just the price of the boiler itself, but also all of the additional components that come with it. These include:

- A drain pump to remove condensate from your system (if you don’t already have one).

- An expansion tank or two (one for each hot water cylinder) to prevent pressure from building up inside your system and causing damage if there are any leaks in pipes or joints connected to them.

Long-term Cost

Fuel Costs

The cost of fuel is one of the major factors in determining your long-term boiler costs. For condensing boilers, the amount of fuel used per year will be lower because it takes less energy to heat water than air.

For example, if you have a 4-ton non-condensing boiler and run it at 80% efficiency for an entire year. With natural gas at $3/m³ and oil at $70/barrel, that would cost about $1120 on average per year. If instead, you had a 4-ton condensing boiler running at 80% efficiency (with no other changes), then this same level of usage would cost approximately $900 per year. So saving around $220 each year!

Maintenance Costs

Condensation can also lead to less wear and tear on parts like pumps and motors–the latter which are prone to breaking down if they’re constantly being used at full capacity (which happens in non-condensing systems). This means fewer repairs overall which will save you some cash over time.

A new condensing boiler can cost up to $ 1,000 less per year in maintenance costs compared with an older one. They also come with warranties that last file for a year or more. Another way they save you money in the long run!

Replacement Parts Costs

Replacing worn-out parts is another area where having a condensing unit gives you an advantage over those with conventional boilers. The cost of replacement parts varies depending on what kind of equipment is needed and how often repairs. However, they’re typically less than $50 per part unless there’s serious damage done during installation itself.

Installation

When it comes to installation, a condensing boiler is more complicated and expensive than its non-condensing counterpart. A non-condensing boiler will typically cost around $1,000 to install. However, a condensing model could cost up to $3,500. Depending on what features you want to be included in your installation such as solar panels or battery storage.

When you install a non-condensing boiler. The heat exchanger is not connected directly to your water tank or cylinder. It’s separated by an air gap. This means that any condensation produced in the heat exchanger can drip down into a tray at its base. Without causing any problems or clogging up pipes.

A condensing boiler has no such luxury. Instead of having an air gap between its water tank and heat exchanger (which would be used as part of its cooling system), both components are directly connected. So they can exchange heat energy in order to keep temperatures stable during operation. This means that any water vapor that builds up inside these parts must be drained out regularly before it becomes dangerous for anyone working nearby!

How to Choose?

The initial cost of a condensing boiler is higher than that of a non-condensing boiler, but the former will save you money in the long run. You can expect to pay anywhere from $2,000-$5,000 more for the installation of a condensing unit than you would for its non-condensing counterpart. However, there are many reasons why this initial investment may be worth it:

- Lower fuel bills: One of the biggest benefits of installing a condensing boiler is that it will help reduce your monthly energy bills because it uses significantly less gas or oil than standard models do. This means that over time you could spend less money on heating costs each month–and therefore have more disposable income left over at the end of each year!

- Longer lifespan: When compared with traditional boilers (which do not have an internal heat exchanger), condensing boilers tend to last longer. Due to their improved efficiency rating and design features. Such as corrosion resistance components like stainless steel heat exchangers which prevent rusting inside pipes.

Conclusion

In conclusion, there are many benefits to having a condensing boiler. It can save you money on your energy bills, it’s more efficient and reliable than non-condensing boilers and they last longer too! If you want to learn more about the difference between condensing and non-condensing boilers, please contact us at +0086 186-2391-5479.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies