Successful Installation of Gas Fired Boiler in Indonesia: Boosting Industrial Efficiency and Energy Transition!

Gas fired boilers are critical components in industrial production, directly affecting project progress through their quality and installation efficiency. Recently, a Chinese gas fired boiler manufacturer successfully completed an order for installing industrial steam boilers in Indonesia. The equipment has been installed and is now operational in Jakarta, where it supports the energy supply system of a local industrial park. This collaboration not only demonstrates the strength of Chinese manufacturing but also provides reliable support for Indonesia’s ongoing industrial energy upgrade.

Why Did Indonesian Industries Choose Chinese Gas Fired Boilers? 3 Key Advantages

-

Robust Design for Tropical Conditions

Indonesia’s tropical climate, marked by high humidity and heat, poses challenges for standard boilers. The newly installed steam boilers feature corrosion-resistant materials and advanced cooling systems, ensuring stable performance and enhanced efficiency even in humid environments. -

Energy-Efficient and Environmentally Friendly

Equipped with low-nitrogen combustion technology and optimized for energy savings, these boilers meet both Indonesian environmental regulations and international standards. This environmentally conscious design supports Indonesia’s sustainable development initiatives. -

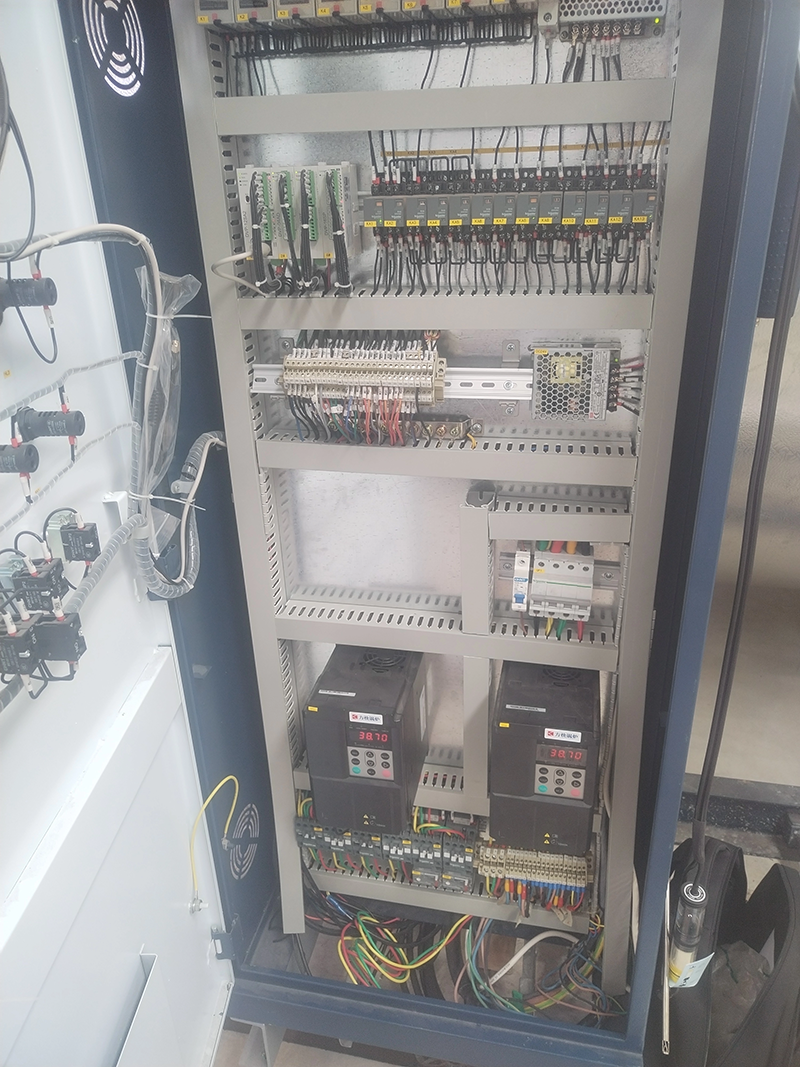

Rapid Installation and Reliable Service

From contract signing to final installation, the project was completed in just 60 days. The manufacturer provided remote commissioning guidance and 24/7 after-sales support, ensuring a seamless integration and ongoing operational reliability.

Overcoming Installation Challenges in Indonesia

-

Navigating Logistical Hurdles:

Indonesia’s vast archipelago presents unique transportation challenges. The manufacturer employed specialized packaging and protective coatings to combat high humidity and prevent corrosion during transit, ensuring the equipment arrives in pristine condition. -

Localization Adaptation:

Electrical components were customized to meet Indonesia’s voltage standards (220V/50Hz), and installation manuals were provided in Indonesian, ensuring ease of use and optimal operation within local settings. -

Certification Compliance:

To facilitate smooth customs clearance and regulatory adherence, all necessary local certifications—such as the SNI (Indonesian National Standard)—were secured well in advance.

Application Scenarios for Chinese Gas Fired Boilers in Indonesia

The installed steam boilers will serve various industrial applications, including:

- Power Plants: Providing efficient steam supply for electricity generation.

- Process Heating: Serving industries such as food and beverage, textiles, and more.

- Urban District Heating: Enhancing heating systems in industrial parks.

- Cogeneration Systems: Integrating with manufacturing complexes to boost energy efficiency.

Installation Experience Sharing

For businesses planning to install or export steam boilers to Indonesia, consider these recommendations:

- Certifications First:

Secure SNI and ISO certifications early to avoid regulatory delays. - Local Partnerships:

Collaborate with Indonesian agents or logistics companies to streamline last-mile delivery and installation across the archipelago. - After-Sales Support:

Establish local spare parts warehouses or maintenance centers to build customer trust and ensure timely service.

About Us

Dabonn Energy Co., Ltd. has been at the forefront of boiler research, development, and manufacturing for 20 years, exporting products to over 50 countries worldwide. We specialize in customized steam boiler solutions. Our dedicated installation team in Indonesia is fully operational and supports both FOB and CIF trade terms. For further inquiries, please contact us at 0086-156-9085-0708

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies