How Much Fuel Does an Oil Boiler Use Per Hour? A Complete Guide

Oil boilers are a popular heating choice for homes, businesses, and industrial facilities due to their reliability and efficiency. But one question often arises: How much fuel does an oil boiler actually consume per hour? Understanding this is critical for budgeting, environmental planning, and optimizing energy use. In this guide, we’ll break down the factors affecting fuel consumption, provide actionable tips to reduce costs, and explore sustainable alternatives.

Understanding Oil Boiler Basics

How Oil Boilers Operate

Oil boilers burn fuel (typically diesel or heavy oil) to heat water or generate steam, which is then circulated to provide warmth or hot water. Key components include:

- Burner: Atomizes fuel and mixes it with air for combustion.

- Heat Exchanger: Transfers heat from flames to water.

- Control System: Regulates fuel flow and temperature.

- Flue: Releases exhaust gases safely.

Modern oil boilers achieve 85–95% thermal efficiency, meaning most fuel energy is converted into heat. However, inefficiencies like heat loss or dirty components can increase fuel use.

Calculating Hourly Fuel Consumption

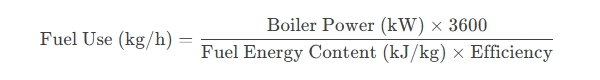

To estimate oil boiler fuel use per hour, follow this formula:

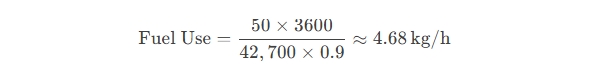

Example Calculation:

- Boiler Power: 50 kW

- Fuel Type: Diesel (energy content = 42,700 kJ/kg)

- Efficiency: 90%

This means a 50 kW boiler burns ~4.7 kg of diesel per hour. For heavy oil, consumption would be slightly higher due to its lower energy content.

6 Key Factors That Impact Fuel Usage

- Boiler Size and Power

Larger boilers consume more fuel but are necessary for high-demand spaces. Oversized units waste energy in smaller settings. - Operating Load

Running at full capacity uses more fuel. Partial-load operation (e.g., 60–80%) can save costs without sacrificing performance. - Fuel Quality

Low-quality oil with impurities burns less efficiently. Stick to certified diesel or kerosene for optimal results. - Maintenance Habits

Dirty burners, clogged filters, or soot buildup reduce efficiency by 10–20%. Schedule annual servicing to avoid waste. - Weather and Insulation

Cold climates and poorly insulated buildings force boilers to work harder, increasing hourly fuel use. - Control Technology

Smart thermostats and zoning systems adjust heating based on real-time needs, cutting idle fuel burn.

Top Tips to Reduce Oil Boiler Fuel Costs

✅ Upgrade to a High-Efficiency Model

Modern condensing boilers reuse exhaust heat, achieving 95%+ efficiency. While upfront costs are higher, long-term savings offset the investment.

✅ Optimize Heating Schedules

Use programmable thermostats to lower temperatures during off-hours (e.g., nighttime or weekends). Even a 1°C reduction can save 5–10% on fuel bills.

✅ Seal Drafts and Improve Insulation

Fix leaky windows, add attic insulation, and insulate pipes. This reduces heat loss, allowing shorter boiler runtimes.

✅ Switch to Biofuels

Blends like B20 (20% biodiesel) burn cleaner and may qualify for green energy incentives. Check compatibility with your boiler first.

✅ Monitor Fuel Use with Smart Meters

Track hourly consumption patterns to identify inefficiencies. Apps like BoilerLink or Heat Spy provide real-time insights.

Real-World Example: Cutting Fuel Use by 18%

A Vermont school district replaced its aging 150 kW oil boiler with a high-efficiency condensing model and implemented smart zoning. Results:

- Hourly fuel use dropped from 14.2 kg/h to 11.6 kg/h.

- Annual savings: 8,400(at0.70/kg diesel).

- CO2 emissions reduced by 12 tonnes/year.

Environmental Impact and Cleaner Alternatives

While oil boilers are effective, burning fossil fuels contributes to CO2 emissions and air pollution. Consider these steps to go greener:

- Hybrid Systems: Pair your boiler with a solar thermal system to preheat water, slashing oil use by 30–50%.

- Heat Pumps: Electric or geothermal heat pumps offer zero-emission heating, ideal for moderate climates.

- Government Rebates: Many countries subsidize eco-friendly upgrades (e.g., UK’s Boiler Upgrade Scheme).

Final Thoughts

An oil boiler’s hourly fuel consumption depends on its size, efficiency, and how well it’s maintained. By adopting smart controls, upgrading insulation, and transitioning to renewable energy, users can significantly lower costs and environmental impact.

Need Help? Consult a certified HVAC technician to audit your system and recommend tailored solutions.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies