Introduction

Industrial steam boilers may seem like relics of the past, conjuring images of coal-fired machines billowing smoke. But modern steam boiler technology has transformed these devices into clean, efficient, and versatile heating solutions.

How does industrial steam work?

Industrial steam boilers generate steam by heating water through various heat transfer methods. This section explores the steam generation process and heat transfer mechanisms in detail.

Steam generation process

Steam generation starts with a heat source heating a tank or chamber filled with water. The heat source can be from combusting fuels like natural gas, oil, or coal. Or it can be from electricity in electric boilers.

As the water absorbs heat, its temperature rises past 100°C to the boiling point. At this stage, bubbles begin forming as pockets of water vapor or steam start emerging.

More heat causes the water to boil rapidly, converting larger amounts to steam. This steam rises and separates from the remaining hot water. The steam accumulates in the upper part of the boiler tank.

The steam is piped out of the steam outlet, usually through a pressure valve. This delivers pressurized steam to wherever its heat energy is needed – an industrial process, power turbine, building heating system, etc.

Heat transfer methods

Industrial steam boilers rely on three heat transfer mechanisms to boil water:

Radiation: Heat radiates from a hot surface like burning fuel or an electric coil. Water absorbs the radiant energy, raising its temperature. Radiation accounts for a majority of heat transfer in boilers.

Convection: Hotter water naturally rises, distributing heat as it moves upwards. Cooler waterfalls to be reheated. This convection current helps heat water evenly.

Conduction: Direct contact between boiler tubes and flames or hot gases transfers heat through metal walls. This heats the water circulating inside.

Conduction and convection transfer heat faster than radiation. Combining all three methods allows industrial boilers to deliver abundant steam rapidly. Modern boiler design optimizes radiation from flames, conduction through tubes, and convection within water to maximize efficiency.

Types of industrial steam boilers

Industrial facilities have different steam boiler options available depending on their needs. The main types include fire tubes, water tubes, and electric, gas, and oil boilers.

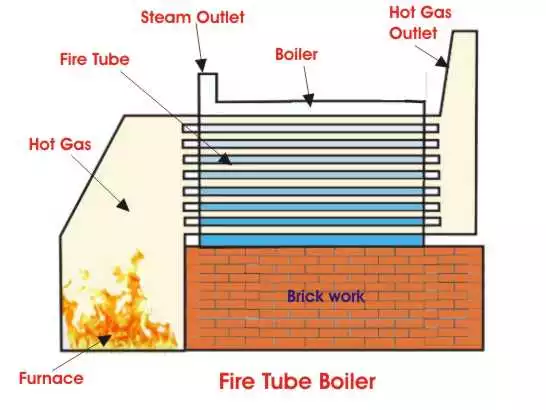

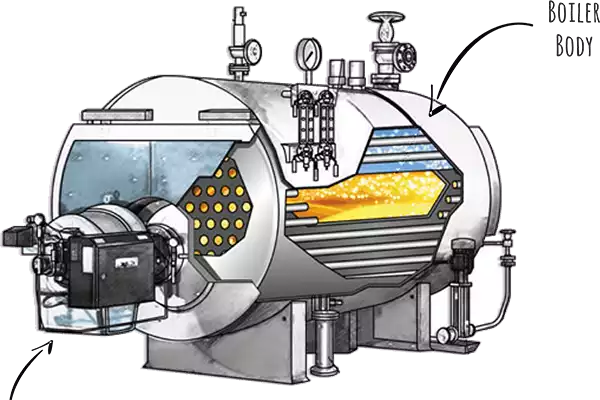

1. Fire tube boilers

In fire tube boilers, hot combustion gases pass through tubes surrounded by water to generate steam. These relatively compact and inexpensive boilers are ideal for low to medium-pressure steam applications up to 15 PSI.

The fire tube boiler design is very simple, it carries hot gases from the burner through pipes in the tank. The gas in the pipes heats the water in the tank to create steam. Since the tube is surrounded by water, heat is transferred from the gas to the water through the metal. This heats the water, turning it into steam, which rises to the top of the tank where it is collected.

Fire tube boilers achieve up to 90% efficiency and are available in different configurations, including vertical, horizontal, and inclined versions. Common types include Cochran, Lancashire, Cornish, and Locomotive fire tube boilers.

Advantages include their compact footprint, fast startup, good steam release, and low cost. Drawbacks are less flexibility in responding to load changes and lower steam pressures compared to water tube boilers.

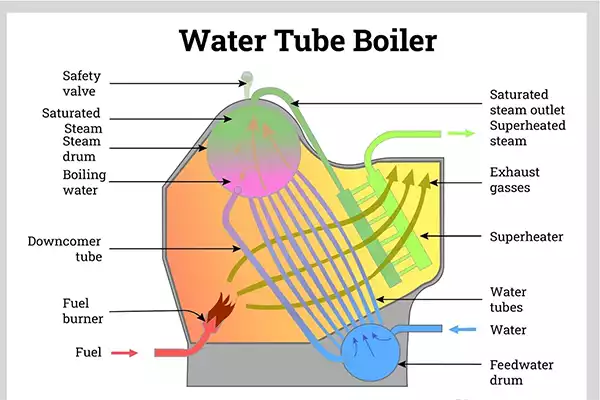

2. Water tube boilers

In water tube boilers, water circulates in tubes with hot combustion gases passing across them to produce steam. More complex and expensive than fire tube types, they can handle high-pressure steam demands for manufacturing plants and power generation.

Water tube boilers consist of a large drum containing water connected to a bundle of smaller-diameter water tubes. The tubes have hot combustion gases flowing around them. When the pipe heats the circulating water, the circulating water can be converted into steam within the pipe. At this point, the steam rises into the drum for collection.

Water tube boilers achieve over 90% efficiency and are available for both high-pressure and low-pressure applications. Common types are LaMont, Benson, and Loeffler boilers.

The advantages of water tube boilers are high steam pressures and the ability to meet sudden steam demands. Downsides include higher complexity and cost.

3. Electric boilers

Electric boilers provide a quick and clean way to produce steam by using electricity to heat water. They provide precision steam temperature and quantity control. Electric boilers suit applications where electricity rates are lower than fuel costs. High operating expenses are their main limitation.

4. Gas boilers

Gas boilers burn natural gas or LP gas to heat water for steam generation. They provide clean and efficient steam with precise control but have higher upfront costs. Gas boilers suit medium-sized industrial facilities.

5. Oil boilers

Oil boilers burn fuel oil to heat water. Though more expensive to run than gas types, they can use cheaper heavy fuels. Fuel storage and handling are challenges. Oil boilers suit industrial applications.

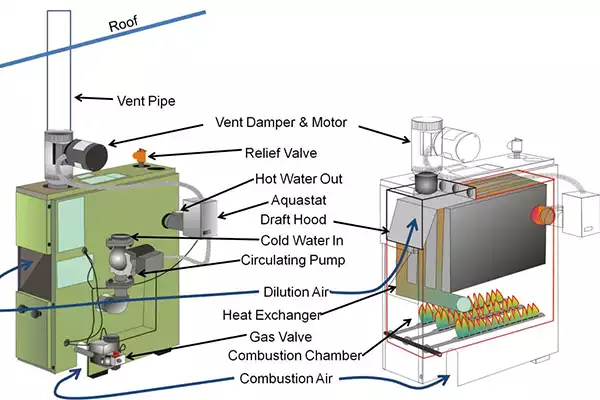

Components of industrial steam boiler

Industrial steam boilers consist of various components working together:

Burner: This device atomizes and mixes fuel with air for combustion. Modern forced-draft burners force air into the fuel stream for complete burning. The burner ignites the mixture to release heat for boiling water.

Combustion chamber: This is an enclosed space housing the burner flames and hot gases. It efficiently transfers heat into boiler tubes and water. Insulation retains heat. Grates support solid fuels like coal or biomass.

Heat exchanger: This network of tubes circulates water while exposed to the hot combustion gases. Heat passes from the gases into the water through tube walls. Hot water enters the top drum, where steam separates. Thermo-siphoning moves water passively. Forced circulation uses pumps.

Steam drum: This large tank collects generated steam while allowing the separation of water droplets. Steam rises into the drum from heated tubes. Dry steam then exits to the distribution line. The drum also houses water level indicators.

Expansion tank: This tank accommodates expanding hot water and fluctuating steam demand. It prevents pressure buildup and keeps the water supply steady. An automatic air vent removes air.

Blowdown valve: This valve periodically removes sludge from the Boiler’s bottom to avoid accumulation. Bottom blowdown valves quickly drain water with sludge and sediment. Surface blowdowns remove dissolved solids.

Safety valves: Pressure relief valves automatically release excess pressure from the Boiler safely. This prevents dangerous over-pressurization and explosion. Valves reseat when normal pressure is reached.

Water level controls: Sensors measure water volume in the Boiler and top up levels when low through automatic valves and pumps. Maintaining proper water levels prevents damage.

Industrial steam boiler efficiency

Operating steam boilers efficiently maximizes steam output while minimizing fuel and energy costs. This section covers methods to improve boiler efficiency and key factors impacting it.

Importance of boiler efficiency

Industrial steam boilers consume large amounts of fuel and energy to deliver steam. Even small efficiency improvements translate into significant savings in fuel, costs, and environmental impact over time.

Efficient systems also generate steam reliably with minimum downtime for repairs. By optimizing efficiency, industrial plants get maximum return on boiler system investment.

Methods to improve efficiency

Various methods can optimize steam boiler efficiency:

- Preheating combustion air: Preheating air entering the burner improves combustion efficiency. The air absorbs heat from flue gases in an air preheater before entering the Boiler. This allows better fuel burn with less heat loss.

- Optimizing excess air: Controlling the oxygen level improves combustion efficiency. Too much air wastes heat. Sensors adjust air intake based on oxygen levels in the exhaust. This maintains optimal excess oxygen levels.

- Cleaning heating surfaces: Soot and scale on tubes act as insulation, reducing heat transfer. Regular cleaning through brushes, blowdowns, and acid washes eliminates these. This improves heat absorption by boiler tubes.

- Recovering waste heat: Flue gases contain heat escaping via the chimney. An economizer recovers some of this waste heat to preheat boiler feedwater. This lowers fuel usage and improves efficiency.

- Monitoring flue gas: Analyzing flue gas composition indicates combustion efficiency. Sensors allow adjusting air, fuel, and flame to minimize excess air and unburnt fuel for maximum efficiency.

Key factors impacting efficiency

Various boiler design factors influence overall efficiency:

Fuel type: The fuel chosen affects achievable efficiency levels. Natural gas and oil reach 85 – 90% efficiency. Solid fuels like coal reach up to 75% efficiency. Fuel costs also impact operating expenses.

Burner design: Well-designed burners distribute air and fuel optimally for complete combustion. This maximizes heat generation from the fuel used.

Precision controls: Boilers with smart, precision controls optimize combustion for peak efficiency. Advanced sensors also enable heat recovery and real-time performance monitoring.

Insulation: Insulating external boiler surfaces reduces heat loss, improving efficiency. Insulated boiler tubes also reduce heat loss from flue gases escaping.

Water treatment: Treating boiler feedwater removes scale deposits and corrosion. This maintains clean internal boiler surfaces for better heat transfer and longevity.

Steam traps: These valves prevent steam loss from piping, equipment, and radiators. This conserves energy that would be lost through leaks or venting.

Optimizing these key design factors results in maximum steam generation using minimum fuel – the key goal of boiler efficiency. Regular tuning and maintenance keep efficiency high over time.

Application industry

Industrial steam boilers are used for heating, cooking, and sterilizing. They are also used in industrial applications such as power plants. There are various types of industrial boilers available for different needs and facility types.

Power generation

Steam boilers produce steam that can be used to run turbines and generate electricity. This is the primary use for steam boilers today, and it accounts for about 61% of their total use worldwide.

These machines heat water to 212 degrees Fahrenheit (100 degrees Celsius). Then, they pump the heated water through pipes into buildings’ radiators. This provides warmth in winter.

These include restaurants, hotels, schools, and hospitals among others which require large amounts of hot water during peak times!

Sterilizing equipment

Industrial steam boilers can also be used as sterilizers in hospitals or kitchens where food preparation takes place. This helps reduce the risk of infection from harmful bacteria being spread around by using traditional methods such as boiling water over high heat levels (which requires constant monitoring).

Industrial steam boiler safety

Safe boiler operation prevents accidents and injury. This section covers steam boiler hazards, safety mechanisms, and maintenance best practices.

Steam boiler hazards and risks

Steam boilers pose various safety risks:

- Explosions from excessive pressure

- Burns from hot surfaces, steam, and hot water

- Asphyxiation from leaking flue gas

- Fires from leaking fuel or oil

- Lack of water causes overheating and tube damage.

- Excess deposits impair heat transfer.

- Operator errors also lead to safety issues.

- Proper mechanisms and training are needed to avoid these risks.

Key safety features and mechanisms

Industrial steam boilers incorporate various safety features:

Water level controls: Level indicators and pumps maintain adequate boiler water volume. Low water cutoffs prevent operation without sufficient water. This avoids explosions from overheating.

Pressure relief balves: These valves automatically release excess steam pressure from the Boiler. This prevents the dangerous buildup of excessive pressure.

Blowdown valves: Blowing down bottom or surface deposits regularly prevents accumulation and efficiency loss. This avoids potential overheating and tube damage.

Flame failure controls: Flame sensors shut off the fuel supply if the pilot light or main burner flame goes out. This prevents fuel leaks and explosions.

Emergency stop buttons: These instantly stop the fuel supply during an emergency, shutting down the Boiler safely.

Maintenance for safety

Proper boiler maintenance enhances reliability and safety:

- Regular inspections check for leakage, corrosion, and component wear.

- Testing safety valves and controls to ensure they activate when needed.

- Monitoring fuel supply lines and steam pipes spots loose connections.

- Water treatment reduces scale and corrosion, which can lead to leaks or failures.

- Proper cleaning of heating surfaces prevents soot buildup and inefficiency.

- With training and preventive maintenance, operators can run industrial steam boilers safely for years.

Initial cost

The initial cost of an industrial steam boiler ranges from $6,500-30,000. They are available in various sizes, pressure, and types. The industrial steam boiler price depends on these factors:

Size of the boiler. A bigger size means a higher cost because it needs more material to make it.

The pressure of the boiler. High-pressure boilers are more expensive than low-pressure ones. Because they require thicker metal sheets or tubes which are harder to make than thin ones.

Type of your industrial boiler. Each one has its own advantages over others but also comes with its own drawbacks as well. Therefore it’s important for you to know how each type works before deciding which one suits your needs best!

Replacement cost.

It is important to know how much an industrial steam boiler replacement costs because it will allow you to be prepared for the cost of installation and maintenance.

If you need to replace an industrial steam boiler, there are a few factors to consider. The first is the size of the system that is going to be replaced. The cost varies based on the size and type of equipment you are looking for. For example, if you have a 10-ton capacity steam boiler and want something similar, then you will likely pay around $25,000-$75,000 depending on the manufacturer and model. If instead, you are replacing an old 90-ton boiler with a new one that has twice as much capacity (180 tons), then it will cost more like $125K-$300K+.

Conclusion.

Industrial steam boilers are versatile workhorses that safely generate abundant steam for diverse heating, sterilization, and power generation applications. When chosen and maintained properly, they provide reliable, efficient performance for decades.

This guide has covered major boiler types, components, efficiency factors, and safety. With this knowledge, you can select optimal boiler configurations for their needs. Proper maintenance and operation procedures keep boilers working at peak capacity. By understanding industrial steam boiler systems, plants can maximize these devices’ value for their heating processes.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies