Introduction

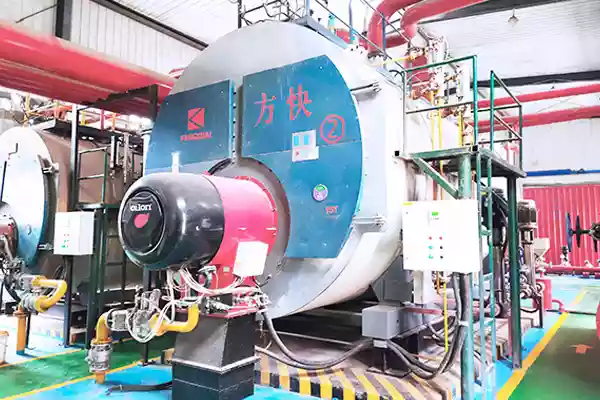

Waste heat boilers are a great way for companies to improve their energy efficiency and reduce the cost of heating and cooling. They can be used to recover waste heat from industrial processes and convert it into steam that can be used to heat systems. Waste heat boilers can be used in several different industries including chemical, petroleum chemical, oil and gas, food, and beverage industries. In this article, you will learn all about it. So that you can make the best choice.

Why waste heat boilers are used?

Reduce energy consumption. Waste heat boilers reduce the amount of energy that you use to heat your building and water by capturing the residual heat from industrial processes and transferring it to your facility.

Reduce greenhouse gases. Waste heat boilers can help you achieve LEED certification, as well as meet EPA requirements for reducing emissions into the atmosphere by capturing carbon dioxide (CO2) and other harmful pollutants created by burning fossil fuels such as coal or natural gas to produce electricity.

Increase efficiency by using less fuel overall. When used in conjunction with an existing boiler system, a waste heat recovery system will increase efficiency and reduce operating costs because it reduces demand for fuel purchases while also improving overall performance at lower temperatures than traditional furnaces alone could provide on their own.

What is a waste heat boiler?

A waste heat boiler uses the exhaust heat from a process to generate steam, which is used in a steam turbine to generate electricity. The advantage of this type of system over other types of power plants is that it does not require additional fuel consumption or CO2 emissions from burning fossil fuels.

Additionally, since waste heat boilers are often used as part of existing industrial processes (such as steel production), they can be installed without significant capital costs or changes in the manufacturing process itself.

Is a waste heat boiler a heat exchanger?

A waste heat boiler is a heat exchanger. A heat exchanger transfers heat from one medium to another. In this case, the low-temperature source is typically water that has been heated by industrial processes such as electricity generation or chemical manufacturing. The high-temperature source could be steam produced in another process, or even waste gas from the combustion of fuel like coal or natural gas. Waste Heat Recovery Boilers (WHRBs) are used to recover this otherwise wasted energy and turn it into usable steam for heating purposes.

How does a waste heat boiler work?

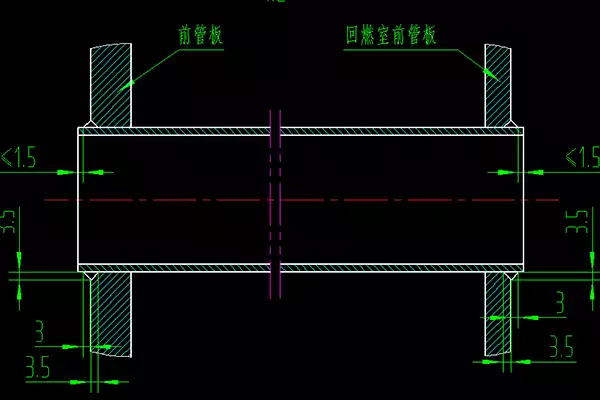

The waste heat boiler is a closed system, which means it uses water as both its working fluid and coolant. The water passes through tubes inside the boiler and absorbs heat from combustion gases or exhaust streams before being cooled back down again by fresh air drawn in through grilles or openings at either end of each tube bundle (called headers).

The process begins when you start up an industrial machine like an electric furnace or combustion engine. Which amounts of excess heat that isn’t required by its main purpose (for example: generating electricity). The waste heat is then transferred via pipes to the boiler where it is used to warm up water. Until it boils into steam at high pressure before being released into the atmosphere through a pipe.

What is the capacity of waste heat boilers?

The capacity of a waste heat boiler is measured in kilowatts (kW). This is the amount of electricity it can produce at any given time. The capacity depends on three factors:

- The efficiency of your heat recovery system, which affects how much waste heat you can use before you start losing efficiency or having to add more water to cool it down.

- The temperature of your source of waste heat, as well as its flow rate (how much air is flowing through it).

- Your needs for electricity, if you only need enough energy for one room’s worth of lights and appliances, then your requirements will be different than someone who needs power for an entire house or building!

What is the efficiency of a waste heat boiler?

A waste heat boiler is not 100% efficient. In fact, it’s usually around 70% to 80%. It’s calculated as the ratio of energy output to input, and it’s usually expressed as a percentage. For example, if your waste heat boiler converts 80 percent of its fuel into useful heat, then its efficiency rating would be 0.8 (or 80%).

So if you have 1 kWh of electricity coming out from your generator which is being used to produce steam for your process, then 0.7 – 0.8 kWh will be lost as waste heat through various processes within the system.

This loss occurs due to friction in pipes and valves as well as heat losses in coils and other components that make up the system itself (like pumps).

What are the components of waste heat boilers?

The main components of a waste heat boiler are:

Primary heat exchanger. This is the part of the boiler that transfers heat from one fluid to another. It’s usually made of copper or stainless steel, with a finned tube design to maximize efficiency.

Water treatment system. A water treatment system helps remove impurities from your water before it goes into your boiler so that it doesn’t clog up pumps or damage other components. There are many different types of treatment systems available depending on what kind of impurities are present in your supply source.

Control system. Waste heat boilers require constant monitoring. They need sensors and software so that you can control temperature levels throughout the operation. As well as detect if there are any problems occurring within the system itself (like leaks).

Boiler feed pump. The boiler feed pump is responsible for pumping water from the hot well, into your heating system. It’s an important component. Because it transfers heat energy to your home or building, which allows you to use less energy on heating costs!

Boiler feed tank. This component holds water at high temperatures so that it can be used by your heating system when needed.

What are the advantages and disadvantages of waste heat boilers?

Advantages of waste heat boilers

Save Energy

Save money on your heating bill by using the wasted energy from other processes in your plant or office building.

Environmental Protection

Reduce emissions because they don’t require burning fossil fuels or producing electricity for heat production.

Running Low Cost

These are less expensive to operate than traditional boilers. Because there is no need for fuel delivery or maintenance costs. Such as filters and pumps associated with traditional boilers that use fossil fuels like natural gas or propane gas (LPG).

Disadvantages of waste heat boilers

Installation Cost Expensive

This is because of the complex nature of waste heat boilers and the expertise required for installation. The installation costs may also vary depending on where you’re located as well as whether you choose an electric or gas-fired boiler system.

More Maintenance

They require a lot of maintenance because they work at high temperatures and generate a lot of heat. This can lead to corrosion if not properly maintained. If your boiler is not properly maintained it could result in poor performance. Even failure causes downtime for your plant/business. This can be very costly especially if no alternative source exists nearby that would allow operations to continue without interruption.

How do I choose a waste heat boiler?

Choosing a waste heat boiler is an important decision. Here are some things to consider:

- The size of the boiler. A large, high-capacity boiler will be more efficient and cost-effective than a small one. But it may not fit your space requirements or budget constraints.

- The heat source used to generate steam (e.g., electricity vs natural gas). If you’re looking for an environmentally friendly option that requires no additional fuel costs. Consider solar thermal panels as an alternative energy source for heating water before using them in your waste heat recovery system!

- Installation costs and maintenance requirements (think about whether you’ll need professional help with installation). If installing yourself isn’t something that sounds fun right now but would rather save money on someone else doing this part for you!

How much does a waste heat boiler cost?

The cost of an waste heat boiler depends on a number of factors including the size, efficiency, and type of HRSG you choose. Smaller units can be purchased for as little as $5,000, while larger ones can cost over $100,000.

A waste heat recovery system is an investment worth making because it allows users to reduce their utility bills by up to 90%. In addition, these systems are environmentally friendly due to their ability not only to recover heat. But also to recycle otherwise unusable materials into usable energy sources such as hot water or steam.

Conclusion

We hope that this article has helped you understand the basics of waste heat boilers and their advantages. Waste heat boilers can help companies save money on energy costs while also reducing their carbon footprint. If you have any questions about waste heat boilers or want more information about how they work, please contact us: +86 18623915479!

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies