What is a Boiler Feed Pump?

At Fangkuai Boiler, we understand the importance of reliable and efficient boiler feed pumps in any industrial boiler system. These pumps play a critical role in maintaining system performance, energy efficiency, and safety. In this article, we will discuss the various aspects of boiler feed pumps, including their role in boiler systems, impact on system performance and energy efficiency, successful implementation examples, and frequently asked questions. We hope this information will help you make informed decisions about your boiler system and ensure that it operates at its best.

Understanding boiler feed pumps.

What is a Boiler Feed Pump?

A boiler feed pump is a type of pump that is used to deliver feedwater to a boiler at the required pressure and flow rate. Feedwater is water that is supplied to the boiler to be converted into steam, which is then used for various industrial processes. Boiler feed pumps are designed to handle high temperatures and pressures, as well as a variety of feedwater types, such as city water, well water, or condensate return. They are typically installed in a boiler feedwater system, which includes other components such as feedwater tanks, deaerators, and preheaters.

How does a boiler feed pump work?

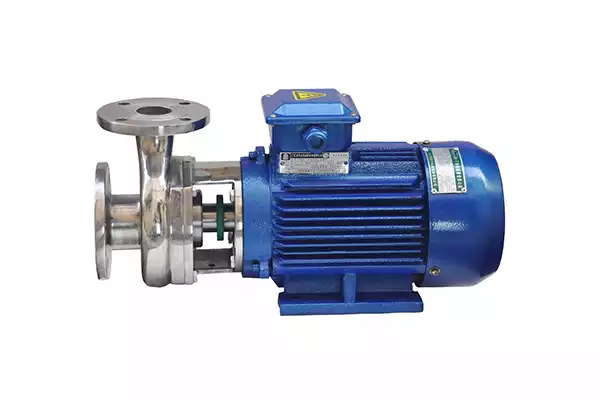

Boiler feed pumps typically operate using centrifugal force, which is generated by the spinning impeller within the pump housing. As the impeller rotates, it creates a low-pressure area at the center, which draws water in through the pump’s inlet. The water then passes through the impeller blades, which accelerate it and increase its pressure, before exiting the pump at a higher pressure and flow rate.

To ensure consistent and accurate feedwater delivery, boiler feed pumps are often equipped with various control mechanisms, such as speed control and pressure sensors. These devices can adjust the pump’s output to meet the changing demands of the boiler system, ensuring that it receives the required feedwater supply at all times.

Types of Boiler Feed Pumps.

There are several types of boiler feed pumps available, each designed to meet the specific requirements of different boiler systems. Here are some of the most common types:

- Centrifugal pumps: These pumps use centrifugal force to increase the pressure and flow rate of the feedwater. They are the most common type of boiler feed pump and are available in various designs, including single-stage, multi-stage, and vertical.

- Positive displacement pumps: These pumps operate by trapping a fixed amount of fluid and forcing it into the boiler, which makes them ideal for low-flow and high-pressure applications. They are often used in boilers that require precise control over the flow rate and pressure of the feedwater.

- Regenerative turbine pumps: These pumps use a unique design to increase the pressure of the feedwater by passing it through multiple stages of impellers. They are highly efficient and are often used in high-pressure and high-temperature applications.

- Boiler feedwater recirculation pumps: These pumps are designed to recirculate feedwater from the boiler back to the deaerator, to reduce the risk of corrosion and improve system efficiency. They are commonly used in large-scale power plants and industrial facilities.

- Multistage pumps: These pumps are similar to centrifugal pumps, but have multiple impellers to increase the pressure of the feedwater in several stages. They are often used in high-pressure applications, such as power generation and petrochemical processing.

Choosing the right type of boiler feed pump depends on factors such as the boiler system’s size, pressure and flow requirements, and the type of feedwater being used.

Benefits of Using a boiler feed pump.

Using a high pressure boiler feed pump can offer several benefits for industrial operations, including:

- Improved system performance: A properly functioning boiler feed pump can help maintain the correct pressure and flow rate of feedwater to the boiler, which is essential for optimal system performance. This can help prevent issues such as overheating, boiler damage, and reduced efficiency.

- Energy efficiency: By maintaining the correct pressure and flow rate of feedwater to the boiler, a boiler feed pump can help improve energy efficiency, reducing fuel consumption and operating costs. This is especially important for large-scale operations that require significant amounts of steam.

- Longer equipment life: By ensuring that the boiler is receiving the correct amount of feedwater at the correct pressure, a boiler feed pump can help extend the life of the boiler and related equipment. This can save money on costly repairs and replacements.

- Reduced downtime: A malfunctioning boiler feed pump can cause downtime, which can be costly for industrial operations. By using a reliable boiler feed pump and performing regular maintenance, downtime can be minimized, ensuring that operations run smoothly and efficiently.

- Improved safety: A properly functioning boiler feed pump is essential for maintaining safe operating conditions in the boiler system. By ensuring that the boiler is receiving the correct amount of feedwater at the correct pressure, the risk of accidents, such as overheating or explosions, can be reduced.

Overall, using a boiler feed pump can offer significant benefits for industrial operations, helping to improve system performance, energy efficiency, equipment life, and safety, while reducing downtime and operating costs.

Boiler feed pump price list.

| Brand | Model | Type | Price Range (USD) |

|---|---|---|---|

| Grundfos | CR series | Centrifugal pump | $2,000 – $15,000 |

| Bell & Gossett | Series e-1510 | Multistage centrifugal | $2,500 – $12,000 |

| Armstrong | 4300 series | Split-case pump | $2,500 – $10,000 |

| Taco | FI series | Inline centrifugal | $2,000 – $8,000 |

| Aurora Pump | 344A series | Split-case pump | $3,000 – $10,000 |

Get an online fixed price in 20 seconds:

Choosing the Right Boiler Feed Pump.

Choosing the right boiler feed pump is crucial for ensuring the efficient and reliable operation of a boiler system. Here are some key factors to consider when selecting a boiler feed pump:

- Pump Type: There are different types of boiler feed pumps available, such as centrifugal pumps, positive displacement pumps, and multistage pumps. Each type has its own advantages and disadvantages, and the selection should be based on the specific needs and requirements of the application.

- Flow Rate and Head: The flow rate and head are important parameters that determine the size and capacity of the pump needed for a particular application. The flow rate refers to the volume of water that the pump can handle per unit of time, while the head refers to the height to which the pump can lift the water. It’s important to select a pump that can deliver the required flow rate and head for the given application.

- Pressure and Temperature: The pressure and temperature of the water being pumped are also important considerations when selecting a boiler feed pump. The pump must be able to handle the maximum pressure and temperature of the water in the system without experiencing any failures or malfunctions.

- Material and Construction: The material and construction of the pump should be carefully evaluated to ensure compatibility with the water being pumped and the operating conditions of the system. For example, if the water contains corrosive substances, the pump should be made of materials that are resistant to corrosion.

- Energy Efficiency: Energy efficiency is another important factor to consider when selecting a boiler feed pump. A pump that is energy efficient can help reduce operating costs and save energy over the life of the system.

Overall, selecting the right boiler feed pump requires careful consideration of various factors and should be done in consultation with a professional or pump supplier.

Get FREE Boiler Quotes

- ✔Get FREE Local Boiler Quotes Today

- ✔Compare The Best Prices

- ✔Save Money On Your New Boiler Today!

Installation and maintenance of boiler feed pumps.

Proper installation and maintenance are essential to ensure reliable operation of boiler feed water pumps. Here are some key considerations for installation and maintenance of boiler feed pumps:

Installation:

- Proper sizing: It is essential to properly size the pump to ensure that it can handle the required flow rate and pressure.

- Correct placement: The pump should be installed in a location that provides easy access for maintenance and repair.

- Adequate space: Adequate space should be provided around the pump for maintenance and repair activities.

- Proper alignment: The pump should be properly aligned with the motor to prevent excessive wear and tear on the bearings.

- Sufficient support: The pump should be properly supported to prevent vibration and misalignment.

Maintenance:

- Regular inspection: Regular inspection of the pump and its components can help identify potential issues before they become major problems.

- Lubrication: Proper lubrication is critical to prevent excessive wear on the pump’s bearings and other components.

- Cleaning: The pump should be regularly cleaned to prevent the buildup of debris or other materials that can impede flow and reduce efficiency.

- Impeller maintenance: The impeller should be inspected and cleaned regularly to prevent damage and ensure optimal performance.

- Seal maintenance: The pump’s mechanical seals should be inspected and replaced as needed to prevent leaks.

Overall, by following the above installation and maintenance guidelines, you can ensure reliable operation of your boiler feed pump and avoid costly downtime and repairs.

Common problems and solutions for boiler feed water pumps.

Boiler feedwater pumps play a critical role in ensuring that the boiler receives the correct amount of feedwater at the correct pressure. However, like any mechanical equipment, boiler-feed water pumps can experience problems from time to time. Here are some of the most common problems and solutions for boiler-feed water pumps:

- Cavitation: Cavitation occurs when bubbles form in the pump due to low pressure and high-speed flow. This can cause damage to the impeller and decrease pump efficiency. To prevent cavitation, it is important to ensure that the pump is properly sized and that the suction line is free of obstructions.

- Mechanical seal failure: The mechanical seal is responsible for preventing water from leaking out of the pump. When the seal fails, it can cause significant damage to the pump and the surrounding equipment. To prevent mechanical seal failure, it is important to regularly inspect and maintain the pump and replace the seal as needed.

- Impeller damaged: Impeller damage can occur due to cavitation or foreign objects entering the pump. This can lead to decreased pump efficiency and potential damage to the surrounding equipment. To prevent impeller damage, it is important to ensure that the pump is properly sized and that the suction line is free of obstructions.

- Overheating: Overheating can occur due to a lack of proper lubrication or insufficient cooling. This can cause damage to the bearings and other components, leading to decreased pump efficiency and potential equipment failure. To prevent overheating, it is important to ensure that the pump is properly lubricated and that the cooling system is functioning properly.

- Low flow rate: Low flow rate can occur due to a variety of factors, including improper sizing, obstructions in the suction line, or worn impellers. This can lead to decreased system performance and potential equipment failure. To address a low flow rate, it is important to inspect and maintain the pump regularly and ensure that the suction line is free of obstructions.

Overall, by regularly inspecting and maintaining boiler feed water pumps and addressing any issues promptly, it is possible to prevent common problems and ensure that the boiler system operates safely and efficiently.

Need a new boiler?

Boiler feed pump FAQs.

What is a boiler feed pump?

A boiler feed pump is a pump that is used to supply water to a boiler at the required pressure and flow rate. The pump takes suction from a deaerator or condensate tank and delivers the feedwater to the boiler through the feedwater control valve.

What are the different types of boiler feed pumps?

There are several different types of boiler feed pumps, including centrifugal pumps, positive displacement pumps, and steam-driven pumps. The type of pump that is best for your system will depend on factors such as system pressure, flow rate, and efficiency requirements.

How do I choose the right pump for my boiler?

Choosing the right pump for your boiler system can be a complex process. Factors to consider include system pressure and flow rate requirements, efficiency requirements, pump size and capacity, and cost. It is recommended that you work with a qualified pump supplier or engineer to determine the best pump for your specific system requirements.

How do I maintain and care for my boiler feed pump?

Proper maintenance and care of your boiler feed pump is essential to ensure reliable and efficient operation. Some maintenance tasks that should be performed regularly include checking for leaks, inspecting the pump and motor, and replacing worn or damaged parts.

What are the common problems with boiler feed pumps?

Common problems with boiler feed pumps can include issues such as low suction pressure, cavitation, overheating, and motor or bearing failure. These problems can result in decreased pump efficiency, increased energy consumption, and potential safety hazards. Regular maintenance and troubleshooting can help identify and resolve these issues before they lead to more serious problems.

How often should I replace my boiler feed pump?

The frequency of boiler feed pump replacement will depend on factors such as pump design, operating conditions, and maintenance practices. Generally, a well-designed and properly maintained pump can last for many years. However, if you notice decreased pump efficiency, increased energy consumption, or other signs of pump wear or damage, it may be time to consider replacement. Working with a qualified pump supplier or engineer can help you determine the best course of action for your specific system.

Conclusion.

At Fangkuai Boiler, we are committed to providing high-quality boiler solutions, including reliable and efficient boiler feed pumps. Our team of experienced engineers and technicians can help you choose the right pump for your system, provide expert maintenance and repair services, and answer any questions you may have. Contact us today to learn more about our products and services, and how we can help you improve your boiler system’s performance, energy efficiency, and safety.

Looking for boilers with sophisticated manufacturing, and great quality?

Fangkuai boiler can always provide what you want.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies