Introduction of CHP / Cogeneration

In the quest for sustainable energy solutions, Combined Heat and Power (CHP) systems stand out as a practical and efficient technology. CHP, also known as cogeneration, simultaneously generates electricity and useful heat from a single energy source, significantly improving energy efficiency compared to traditional systems. This article explores the principles, benefits, challenges, and applications of CHP systems, demonstrating their critical role in modern energy strategies.

Understanding Combined Heat and Power

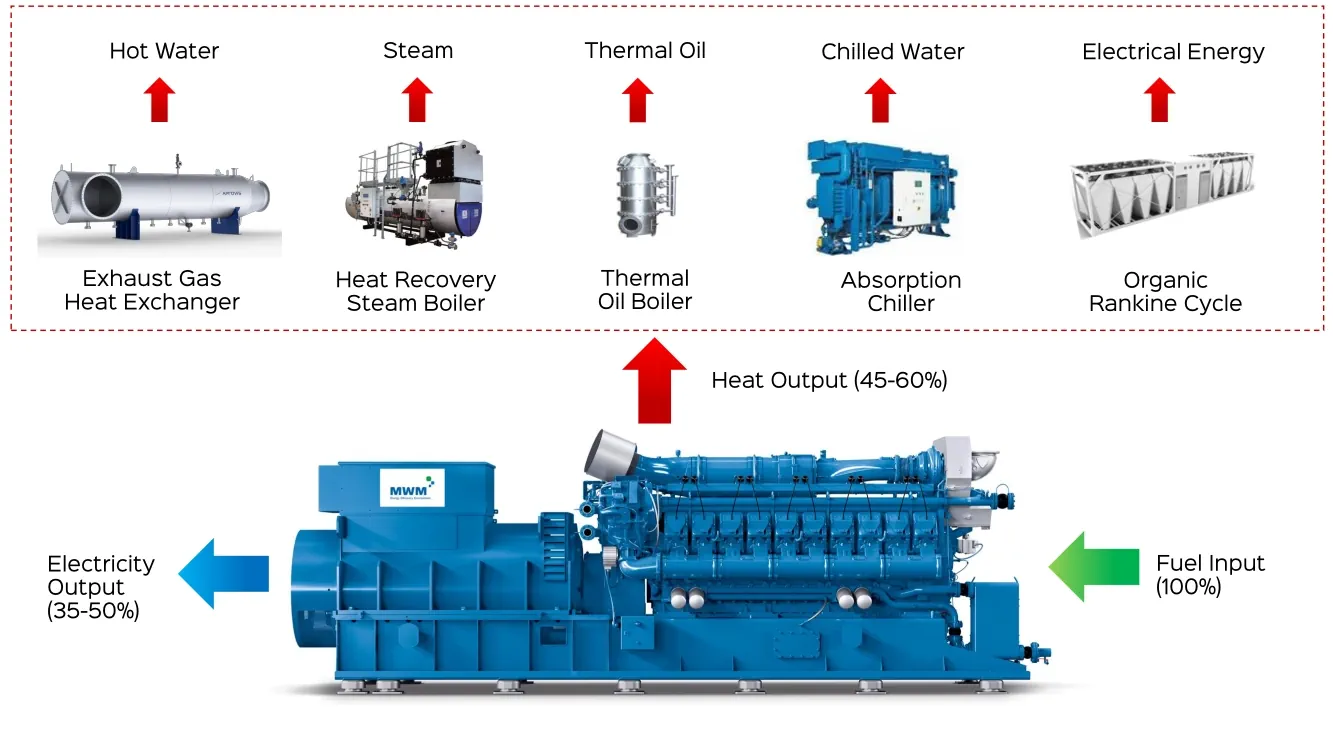

At its core, a CHP system generates electricity through an engine, turbine, or other power-producing device. During this process, a significant amount of energy is released as heat. Unlike conventional systems that discard this waste heat, CHP systems capture and repurpose it for various heating needs, such as space heating, water heating, or industrial processes.

CHP systems are designed to operate near the point of use, which minimizes energy losses associated with electricity transmission over long distances. This distributed energy approach enhances reliability and energy security.

Working Principles of CHP / Cogeneration?

A fuel source (fossil or renewable) is combusted, and the energy produced is used to drive a prime mover (reciprocating engine or gas turbine) which produces mechanical power and heat. The mechanical power is converted into electricity via an alternator and the heat is available to use directly or converted to meet the requirements of the site.

The basic structure of the cogeneration (CO-GEN) thermal power system includes the following components:

– Main equipment: Boiler, turbine, condenser, boiler feed pump.

– Auxiliary equipment: Cooling tower, circulating water pump, condensate pump, deaerator, heat exchanger.

Benefits of CHP / Cogeneration

If your organisation utilises power, heat, steam, cooling, and CO2 in your operations and processes, then CHP, Trigeneration, or Quadgeneration should be considered part of an energy strategy. It doesn’t fit every organisation, but where it does, CHP can deliver substantial benefits such as:

- Reduce or manage energy costs

- Improvement of carbon footprint

- Flexibility in operation helping to manage energy demand and supply

- Improvement in energy resilience

- Future proofing your site from uncontrollable external energy factors

- Cogeneration of heat and electricity from a single fuel input

- Highly energy efficient

- Co-locate additional technologies such as solar PV, battery energy storage, and/or standby power generation as part of a hybrid power solution

The above are just some of the many benefits of CHP compared to traditional means of separately generating power and heat.

Applications of CHP / Cogeneration

1. Industrial Use

Industries such as chemical manufacturing, pulp and paper, and food processing often require both electricity and heat in their operations. CHP systems provide a cost-effective and reliable energy solution for these sectors.

2. Healthcare Facilities

Hospitals need uninterrupted electricity and heating to power medical equipment and maintain indoor climate control. CHP systems ensure energy reliability while reducing operational costs.

3. Commercial Buildings

Large office complexes, hotels, and shopping malls use CHP to meet their electricity, heating, and cooling demands. The reduced energy costs and carbon footprint make it a preferred choice for commercial applications.

4. Data Centers

Data centers consume vast amounts of energy to power servers and cooling systems. CHP systems improve energy efficiency and provide a reliable power source.

5. Residential and Community Heating

CHP systems are used in district heating networks, providing communities with centralized heating and electricity. Micro-CHP units are also available for single-family homes.

Types of CHP / Cogeneration

- Gas Turbine CHP

Gas turbines are commonly used in large-scale CHP systems. They are ideal for industrial facilities and district heating networks. - Steam Turbine CHP

Steam turbines utilize steam from a boiler to generate electricity. They are particularly suited for applications with high steam demands. - Reciprocating Engine CHP

Internal combustion engines are used in small to medium-sized facilities, such as hospitals and small industrial plants. - Micro-CHP

Designed for residential and small-scale applications, micro-CHP units provide electricity and heat to single homes or small businesses. - Fuel Cell CHP

Fuel cells generate electricity and heat through electrochemical processes, offering high efficiency and low emissions.

Conclusion

Combined Heat and Power systems are a practical and proven solution for improving energy efficiency, reducing environmental impact, and enhancing energy reliability. While challenges such as high upfront costs and regulatory barriers remain, the long-term benefits of CHP far outweigh these drawbacks.

As the world faces increasing energy demands and environmental challenges, the adoption of CHP systems represents a step toward a sustainable and resilient energy future. By leveraging this innovative technology, industries, communities, and governments can achieve greater energy independence while contributing to a cleaner, greener planet.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies